PAKETTO 5050K - VMDS

Packaged Products

Kilograms Filled

Packages Filled

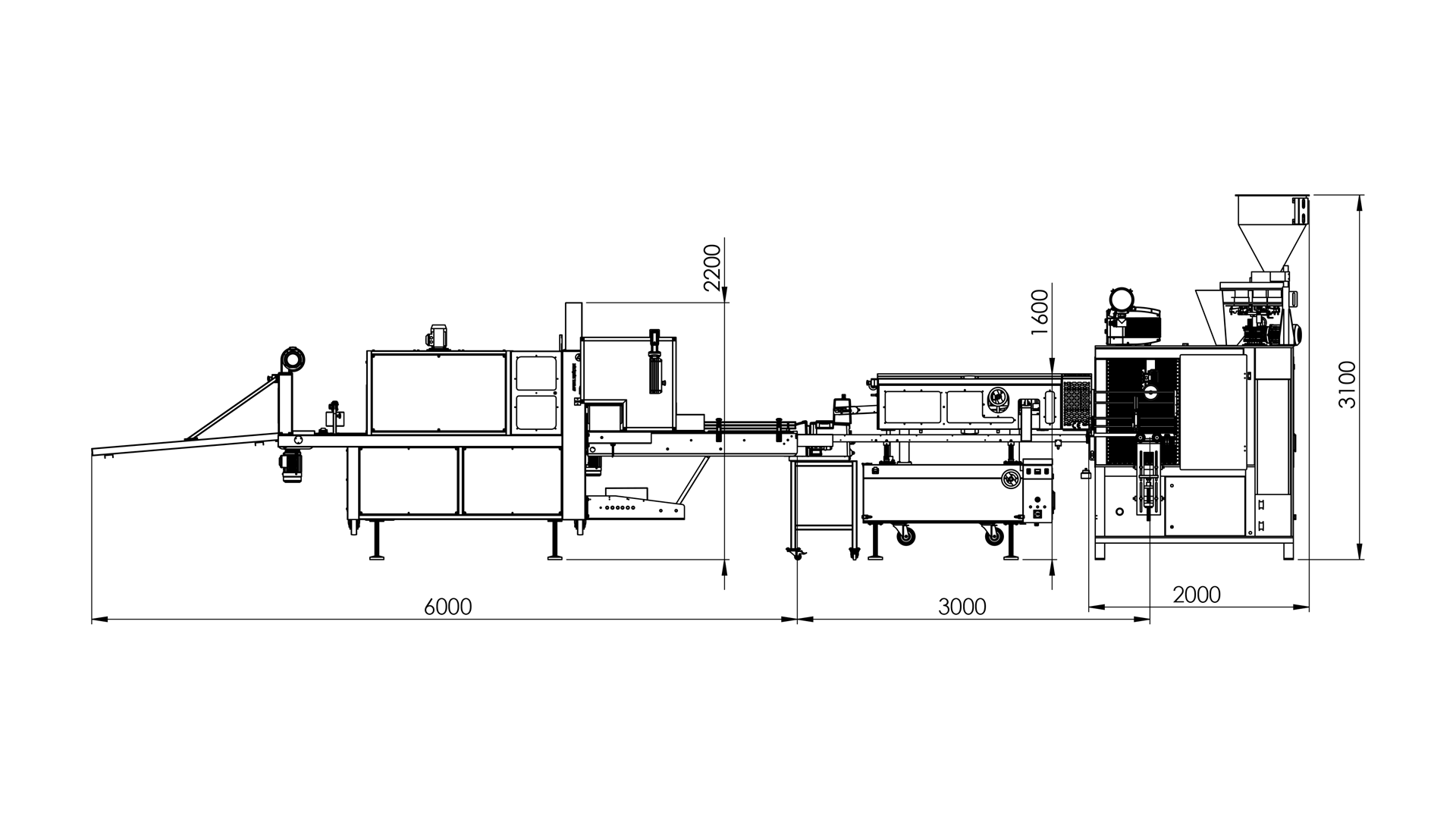

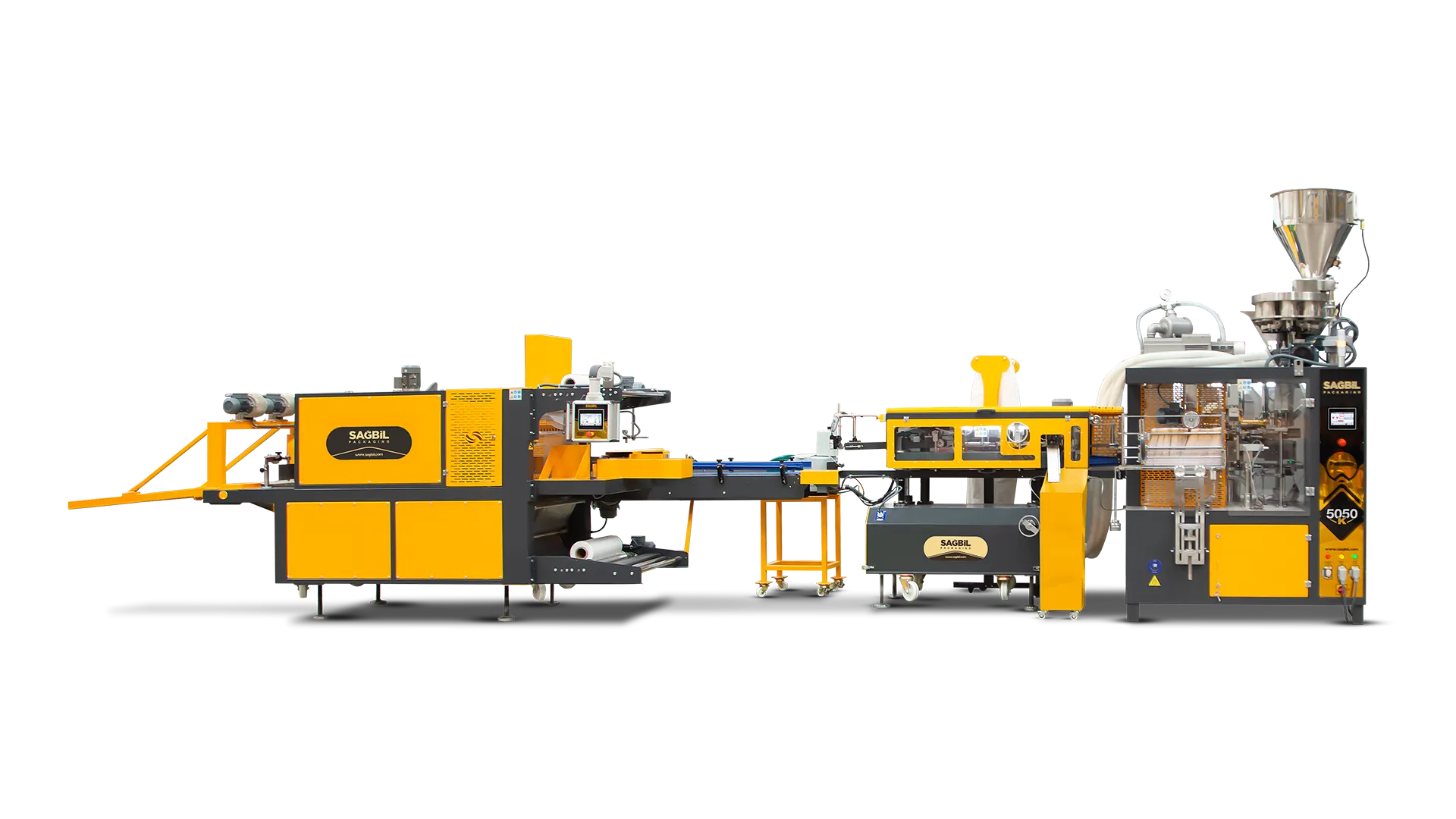

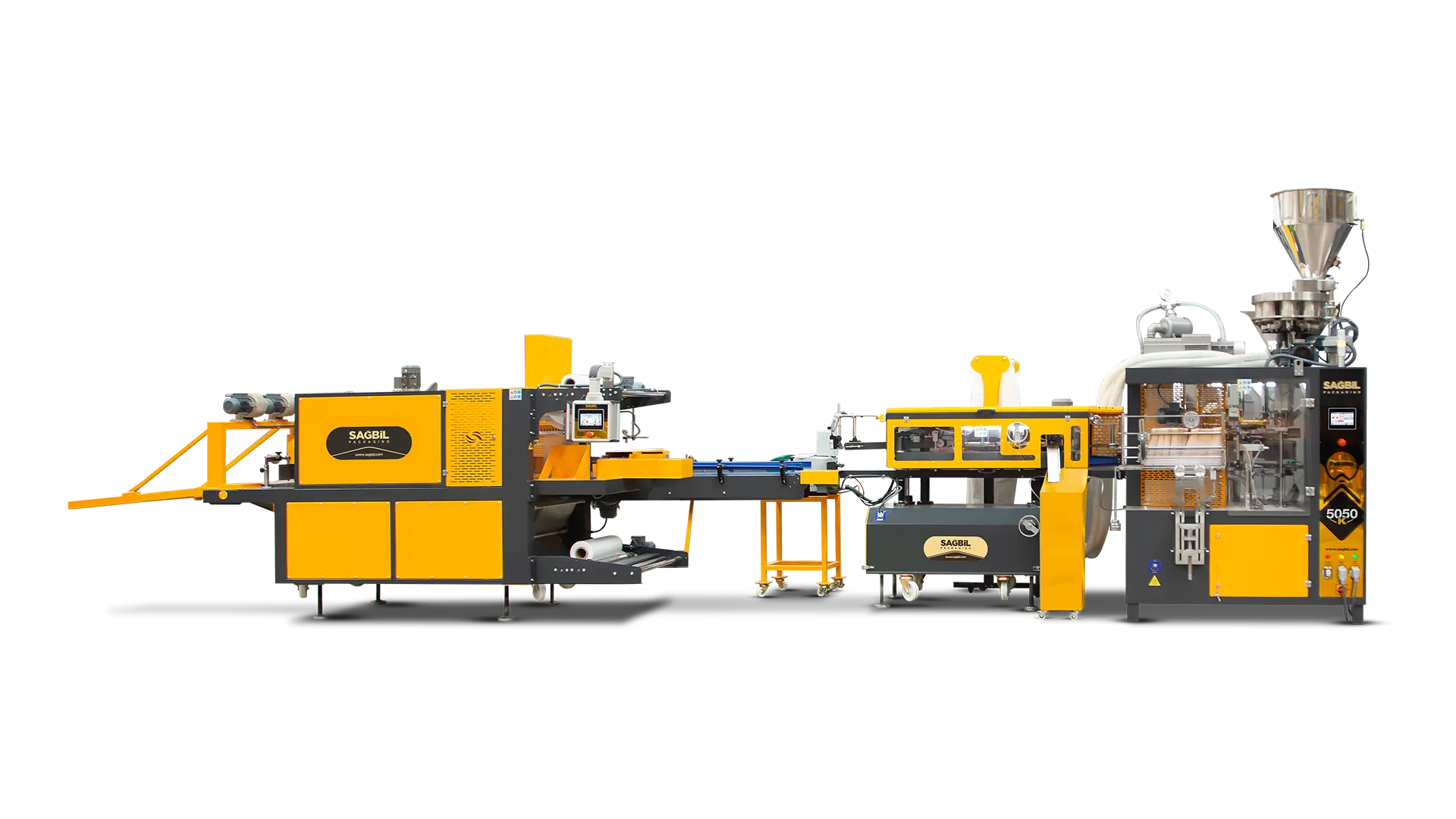

Paketto 5050 K - VMDS: Volumetric Filling & Shrink Wrapping Line

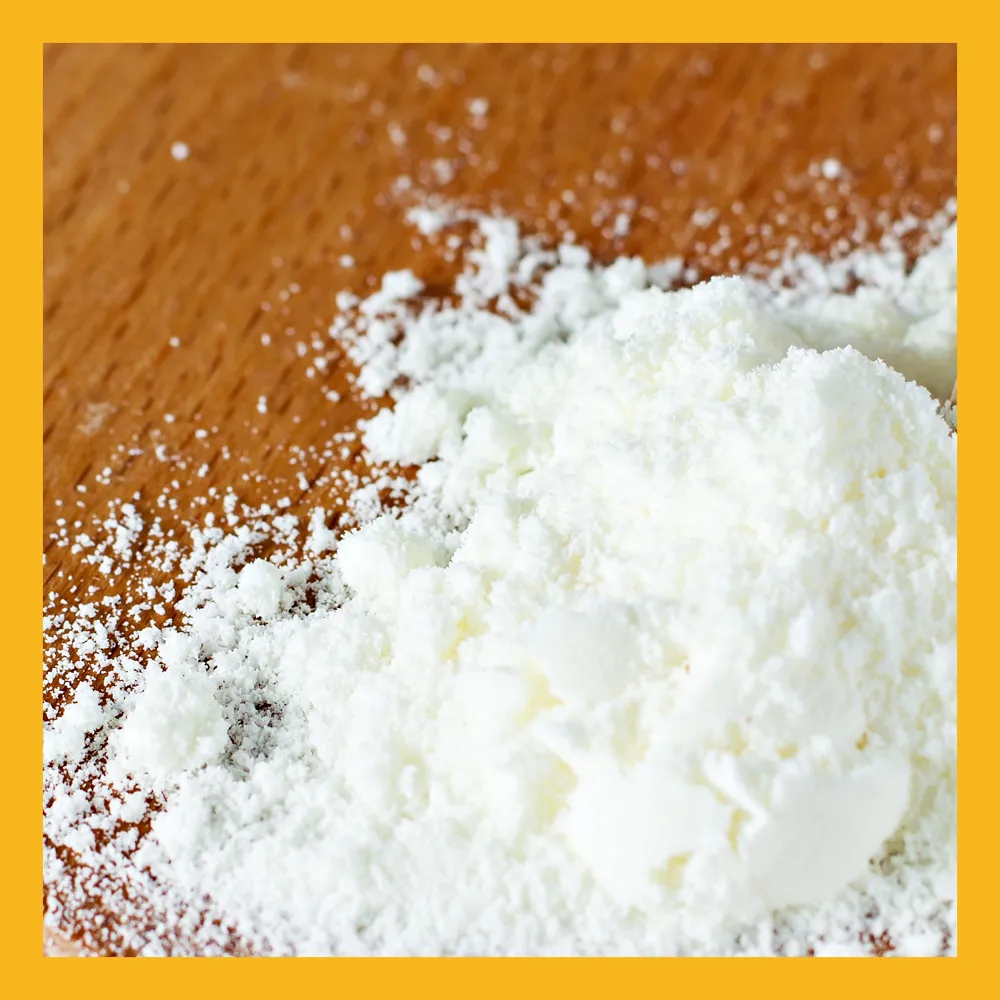

Designed for granular products requiring high speed and fluidity, the Paketto 5050 K - VMDS adds maximum efficiency to your production line. This fully automatic bag filling machine takes its name from its Volumetric Filling system, which ensures rapid and consistent filling for free-flowing products like salt, sugar, powder detergent, and pulses.

With a high speed of up to 50 packs per minute, it performs filling into 1 kg, 2 kg, and 5 kg kraft bag packaging with a precision of under 1%. As a versatile Paper Bag Filling and Packaging Machine, it automatically directs packages to the integrated Shrink Wrapping unit after filling. Here, packs are grouped with protective film (e.g., 2x4) and made ready for shipment.

With its robust structure and premium components, the Paketto 5050 K - VMDS Volumetric Filling & Shrink Wrapping Line offers uninterrupted, high-capacity production for manufacturers. It stands as a superior pulses packing machine, semolina packaging solution, and spice packaging machine, delivering the reliability expected from top-tier bag filling equipment.

You can review our Paketto 5050K product series or visit our Paper Bag Filling and Packaging category.