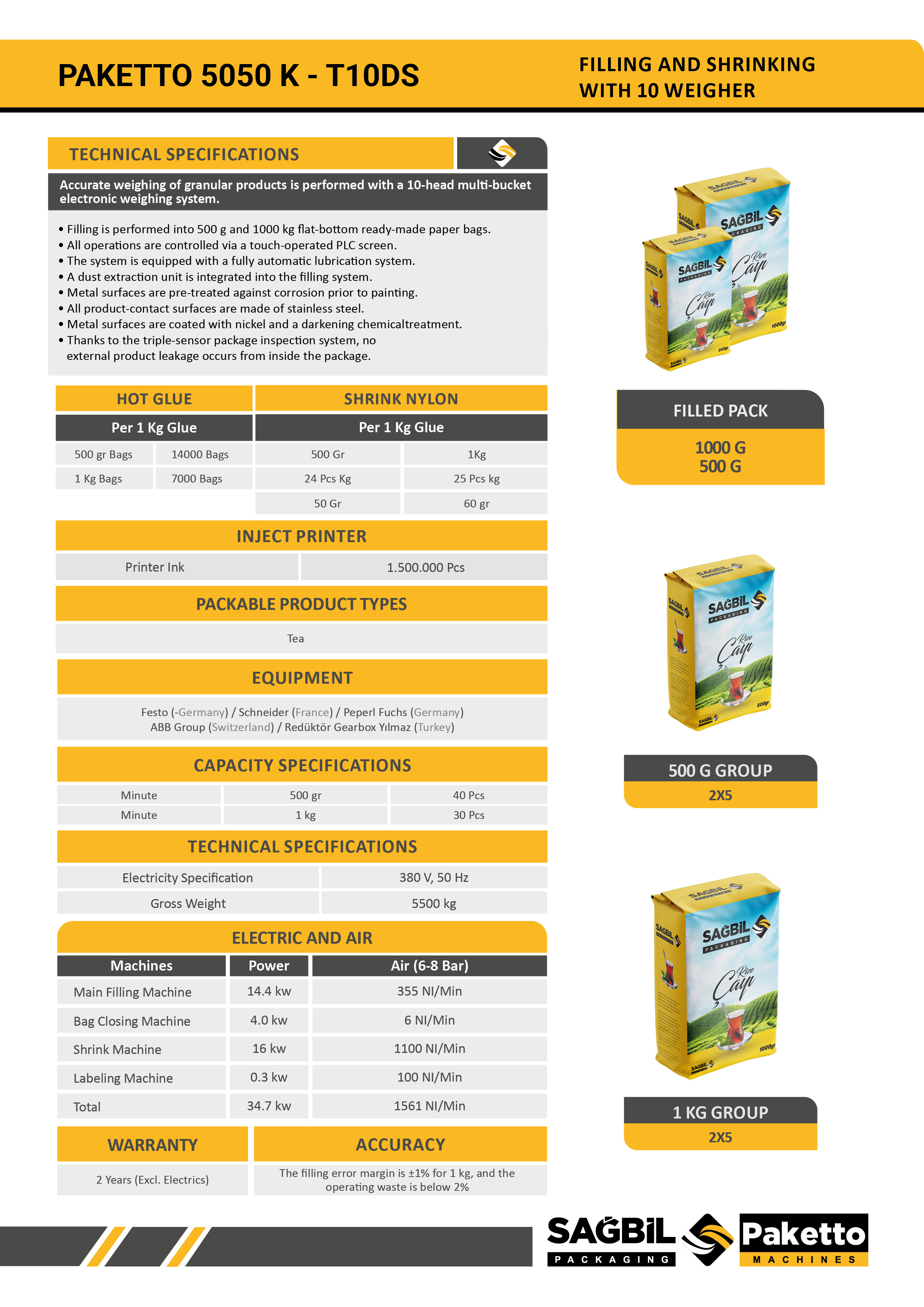

PAKETTO 5050K - T10DS

Packaged Products

Kilograms Filled

Packages Filled

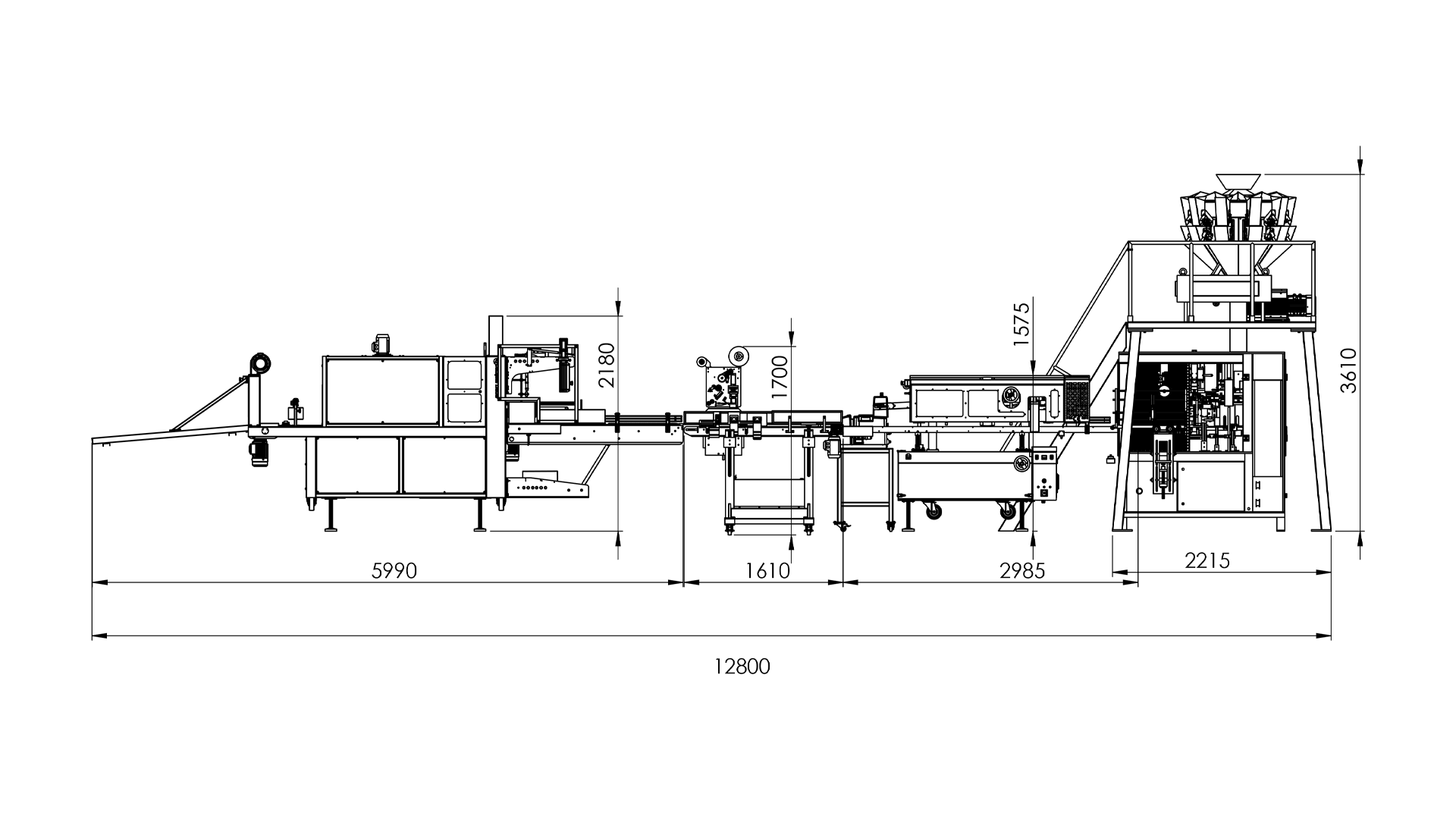

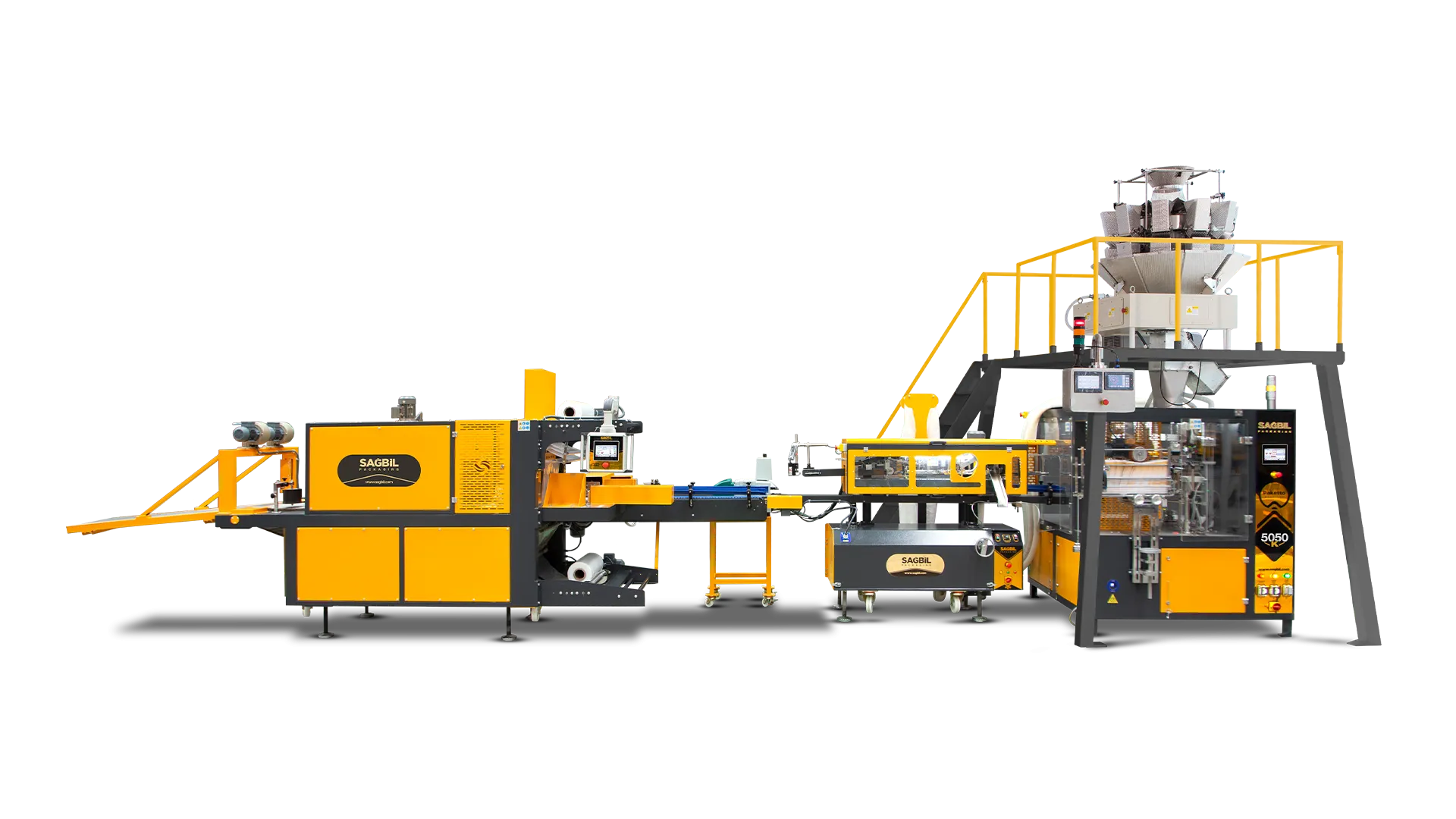

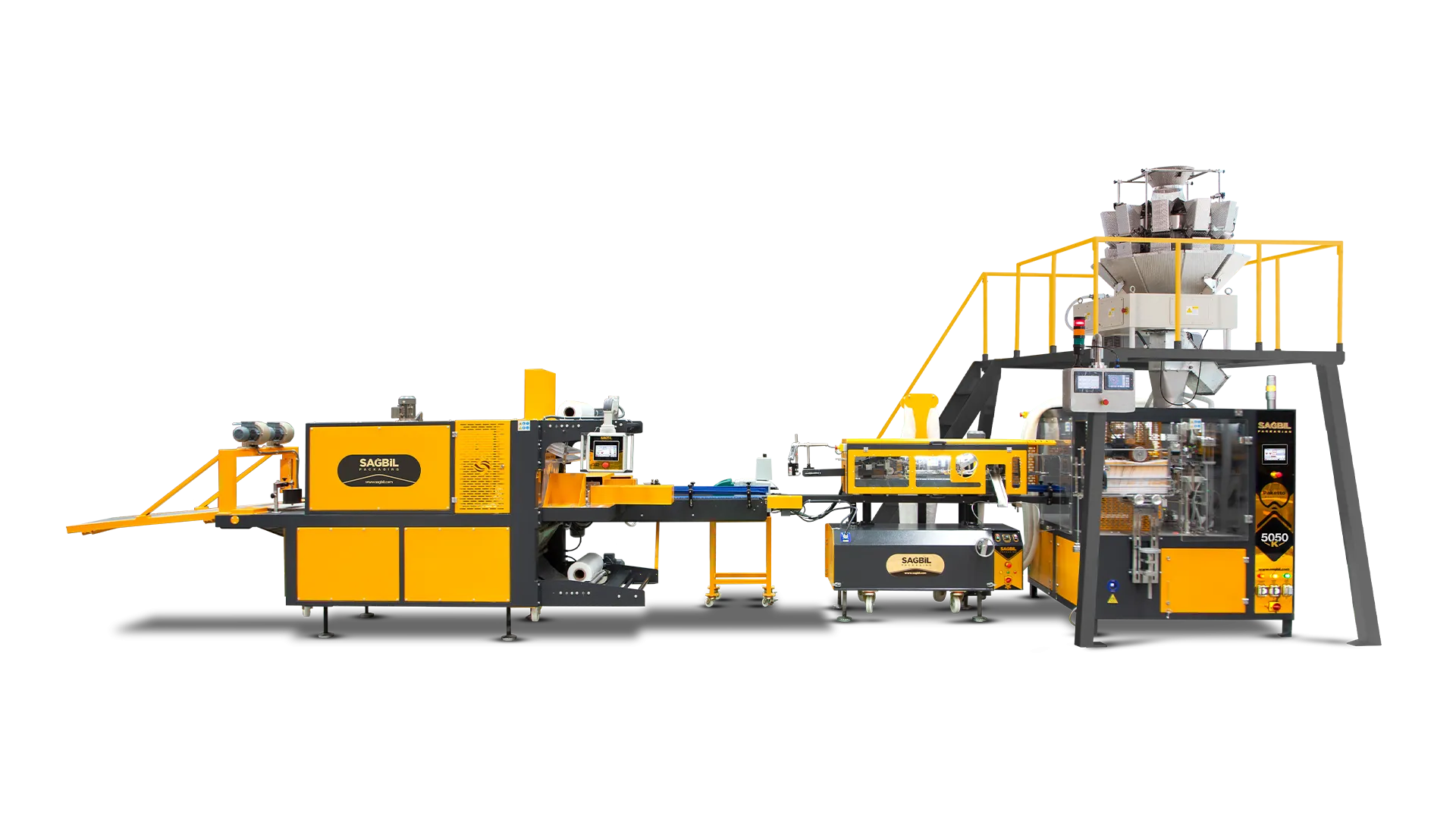

Paketto 5050K - T10DS: 10-Head Multihead Weigher Filling & Shrink Line

Developed specifically for high-value products where grammage accuracy is critical, the Paketto 5050K - T10DS offers the highest level of precision in packaging technology. This fully automatic bag filling machine takes its name from its advanced 10-Head Multihead Weigher system, ensuring every package is perfectly weighted. This technology significantly minimizes waste, making it the ultimate tea packing machine and spice packaging machine.

Operating at speeds of up to 40 packs per minute, it fills elegant 500g and 1 kg kraft bag packaging. Following the filling and labeling process, the integrated Shrink Wrapping unit groups the packages (e.g., 2x5) with protective film, preparing them for shipment.

Designed to meet the high quality and efficiency expectations of producers, this PLC-controlled Paper Bag Filling and Packaging Machine excels as a pulses packing machine for premium brands. Combining speed with precision, this bag filling equipment protects the value of your product.

You can review our Paketto 5050K product series or visit our Paper Bag Filling and Packaging category.