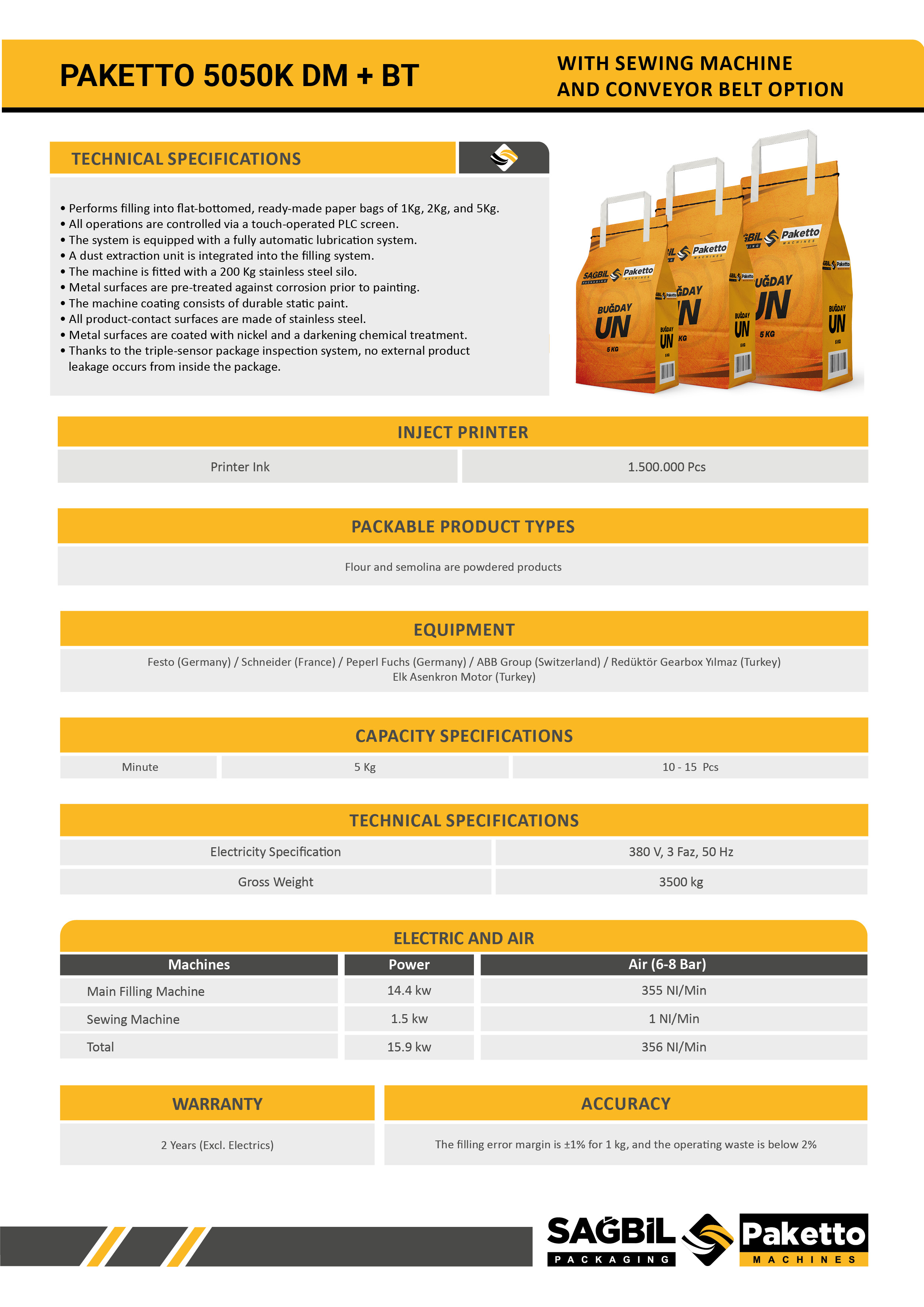

PAKETTO 5050K DM+BT

Packaged Products

Kilograms Filled

Packages Filled

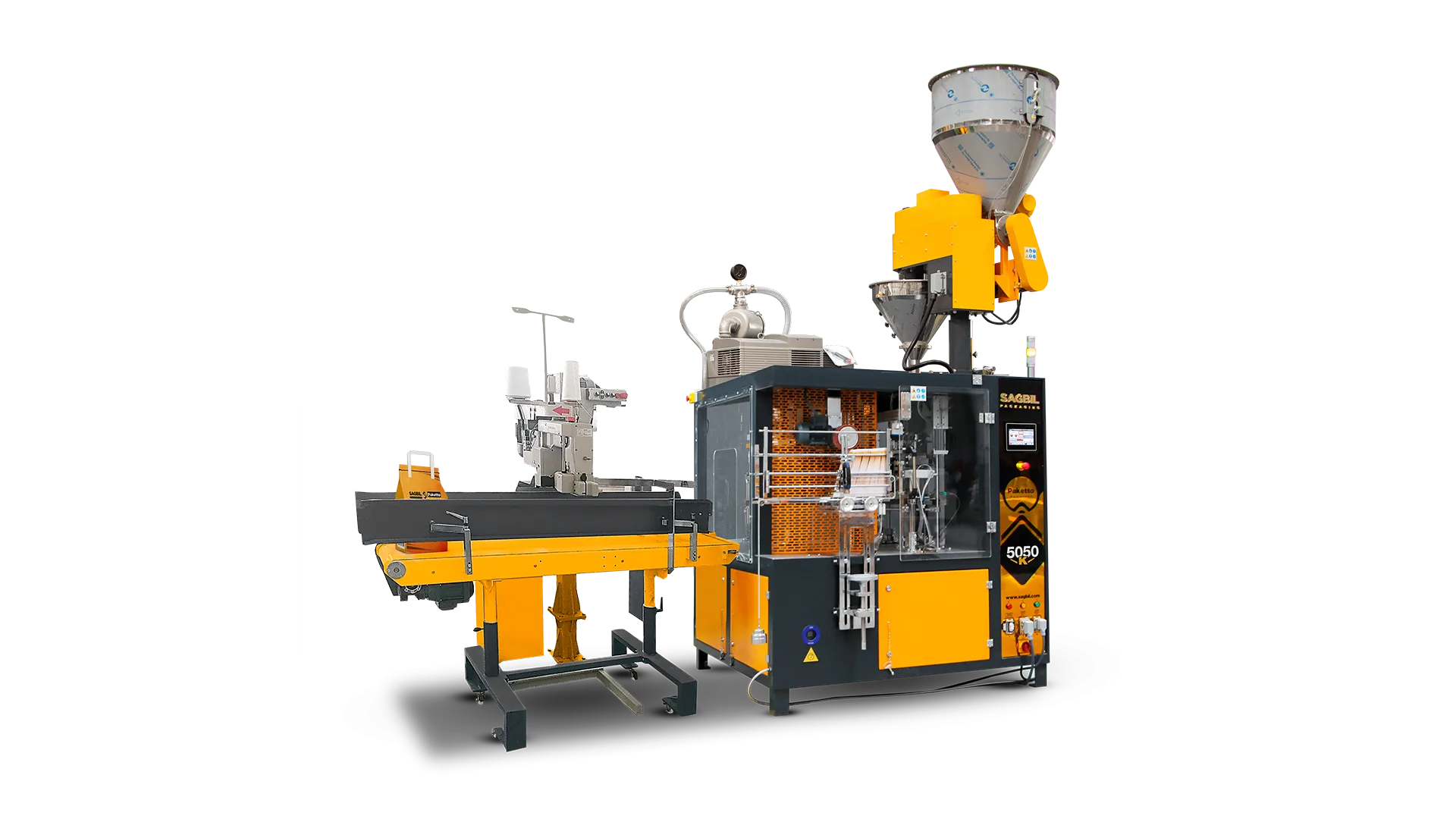

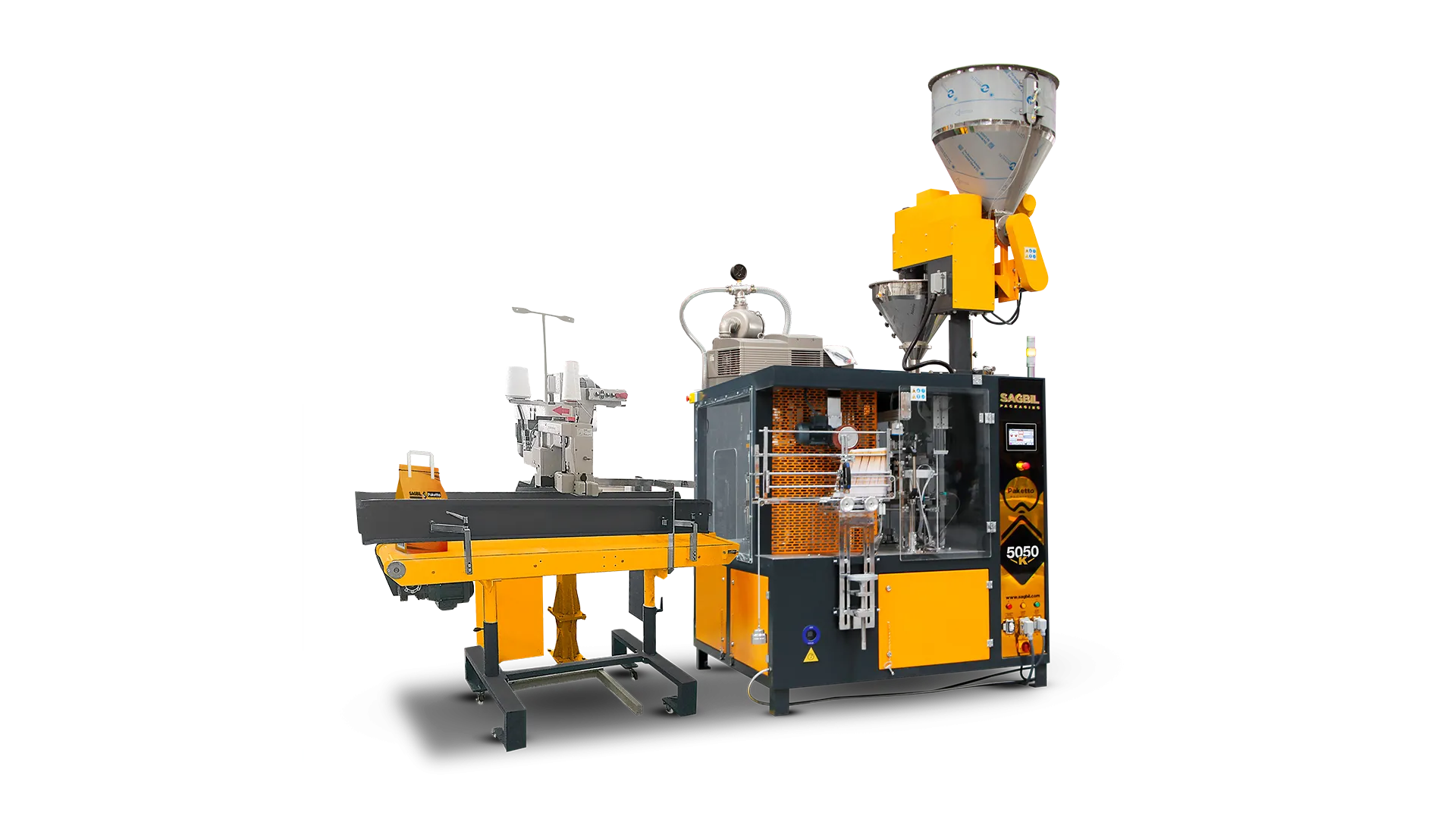

Paketto 5050 K - DM + BT: Sewing Machine with Conveyor and High Performance Packaging

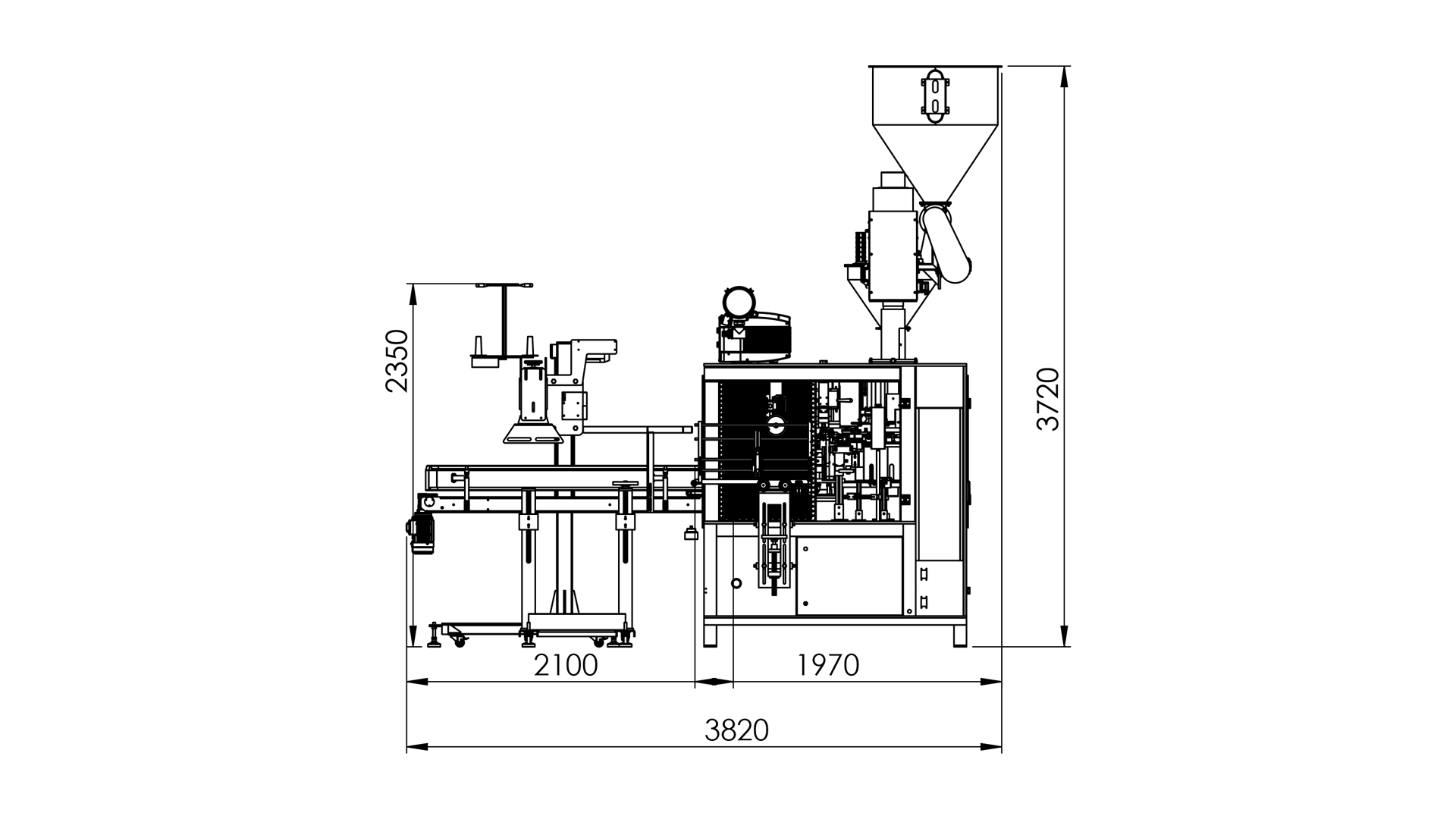

Designed for heavy-duty products requiring extreme durability, the Paketto 5050 K - DM + BT offers maximum security in package sealing after filling. This Sewing Machine with Conveyor and High Performance Packaging option is ideal for large-volume 5 kg kraft bag packaging of powder products like flour and semolina packaging.

This Paper Bag Filling and Packaging Machine automatically transports bags to the sewing unit on a conveyor belt following the precise filling process. The integrated sewing machine seals the bag mouth with a robust stitch, eliminating the risk of tearing or bursting during transport and storage, distinguishing it as a reliable flour paper bag packing machine.

With a capacity of up to 15 packs per minute, this flour packing machines line offers a packaging process that is both efficient and extremely durable, guaranteeing your products reach the customer safely. It stands as a professional solution for productions where strength and safety are paramount, serving as a robust automatic flour packing machine and essential bag filling equipment.

You can review our Paketto 5050K product series or visit our Paper Bag Filling and Packaging category.