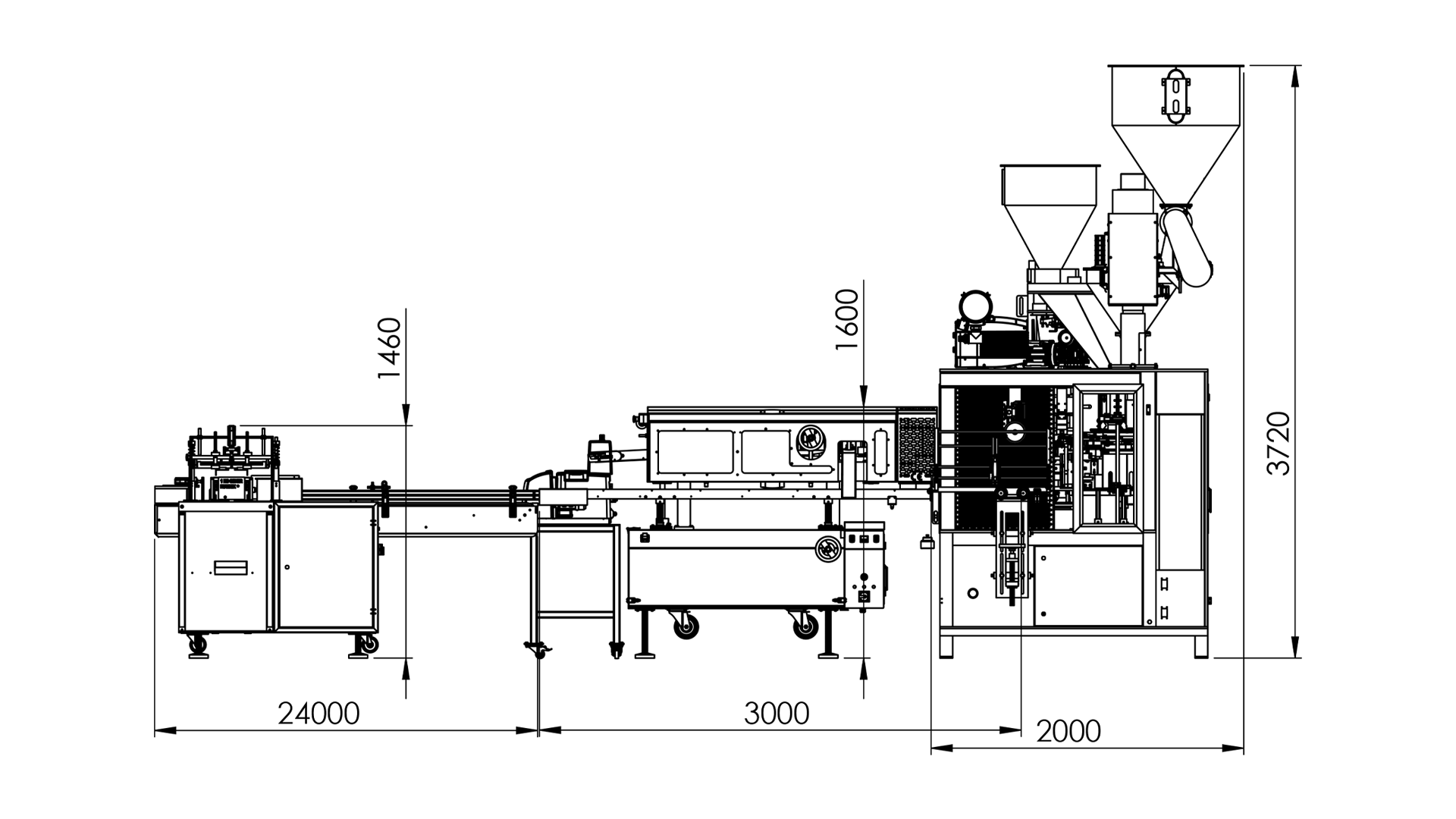

PAKETTO 5050K - VD+VMDB

Packaged Products

Kilograms Filled

Packages Filled

Paketto 5050K - VD + VMDB: Hybrid Auger & Volumetric Filling Baling Line

Designed for manufacturers seeking maximum flexibility to package multiple product types on a single line, the Paketto 5050K - VD + VMDB is a hybrid model offering superior versatility. This advanced automatic bag filling machine integrates both Auger Filling and Volumetric Filling systems, providing a significant production advantage.

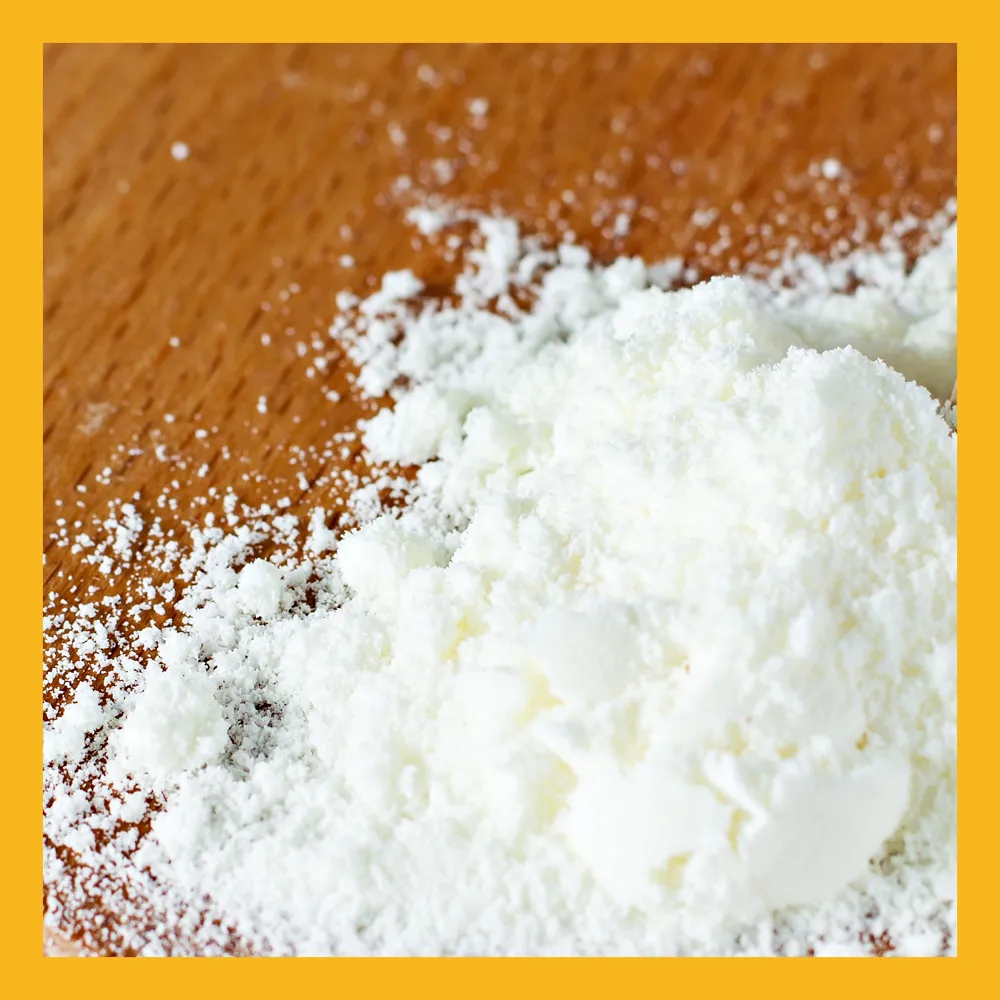

With this dual technology, you can package fine powders like flour and starch with auger precision, while handling free-flowing granules like salt, sugar, and pulses with volumetric speed. Serving effectively as both a flour packing machine and a high-speed packing machine for pulses, it performs filling into 1 kg, 2 kg, and 5 kg kraft bag formats at capacities up to 50 packs per minute. Following filling, the integrated baling unit compresses packages into sturdy, logistics-ready bales.

Eliminating the need to switch machines for different product ranges, this Paper Bag Filling and Packaging Machine combines efficiency and flexibility. It stands as the ultimate flour paper bag packing machine and spice packaging machine solution for diverse industrial needs.

You can review our Paketto 5050K product series or visit our Paper Bag Filling and Packaging category.